CNC-cut foam inserts from Holland, Ohio, offer tailored protection for electronic components during transport and storage. These custom solutions come in ESD-safe and anti-static varieties, addressing critical electrostatic discharge risks while ensuring snug fits with no voids. Lightweight yet robust, they enhance efficiency and safety, extending product lifespans in the tech industry by globally meeting diverse packaging needs.

“Unveiling the Power of CNC-Cut Foam Inserts: A Revolutionary Solution in Electronics Packaging

In today’s advanced world, protecting delicate electronic components during transportation is paramount. This is where protective foam inserts step in as unsung heroes. From bustling factories in Holland, Ohio, to global markets, custom foam inserts are transforming packaging. They offer not just protection but also customization and anti-static properties, ensuring ESD safety—a critical factor for sensitive electronics.

This comprehensive guide explores the role of CNC-cut foam inserts, their applications, and benefits, shedding light on why they’re indispensable in modern electronics packaging.”

- Understanding CNC-Cut Foam Inserts: A Comprehensive Guide

- The Role of Protective Foam Inserts in Electronics Packaging

- Customization: Creating Anti-Static Foam for Specific Electronics

- ESD Safety: Why It Matters and How Foam Inserts Ensure Protection

- Applications and Benefits: From Holland, Ohio, to Global Markets

Understanding CNC-Cut Foam Inserts: A Comprehensive Guide

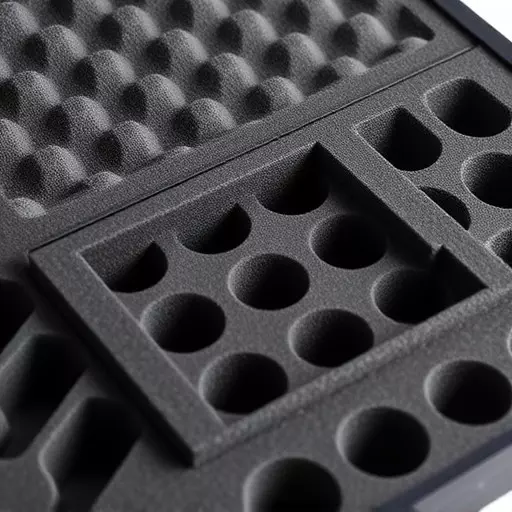

CNC-cut foam inserts are precise and customized protective solutions tailored to specific needs, particularly in the realm of electronics packaging and storage. These innovative inserts are designed to offer optimal protection for delicate electronic components during transportation and storage, making them indispensable for businesses dealing with sensitive equipment. By utilizing Computer Numerical Control (CNC) technology, these foam inserts can be crafted from a variety of materials to meet diverse requirements.

Custom foam inserts come in various forms, including ESD-safe options that are crucial for preventing electrostatic discharge, which can damage electronics. Anti-static foam for electronics is a prime example of such specialized protection, ensuring the safety of components during handling and movement. The process involves sophisticated machinery that cuts and shapes foam with unparalleled accuracy, resulting in inserts that perfectly fit containers or compartments, thereby eliminating voids where damage could occur. This comprehensive guide highlights the importance of these custom solutions in maintaining the integrity of electronics, especially when considering protective foam inserts for electronics Holland Ohio offers.

The Role of Protective Foam Inserts in Electronics Packaging

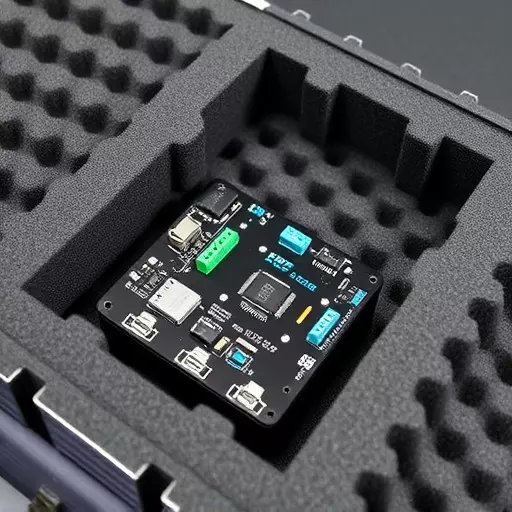

Protective foam inserts play a crucial role in ensuring the safe transportation and storage of electronic components. In the dynamic world of electronics packaging, where devices are becoming smaller, more intricate, and sensitive to static electricity, custom foam inserts offer unparalleled protection. These ESD-safe (Electrostatic Discharge) foam products are designed to accommodate unique product shapes and sizes while shielding them from potentially damaging electrical charges. By using anti-static foam for electronics in Holland, Ohio, manufacturers can mitigate the risk of static discharge, ensuring the integrity of their delicate components during transit.

Custom foam inserts provide more than just ESD protection; they also offer excellent shock absorption, preventing physical damage to electronic devices during handling and shipping. The foam’s ability to conform to irregular shapes ensures that no gaps exist between the product and the packaging material, eliminating the potential for movement and resulting in less risk of impact-related damage. With their versatile applications, these protective foam inserts are a game-changer in electronics packaging, fostering efficiency, safety, and product longevity.

Customization: Creating Anti-Static Foam for Specific Electronics

In the realm of electronics manufacturing, customization is key to ensuring optimal protection. One such tailored solution are CNC-cut foam inserts, designed specifically for sensitive electronic components. These custom foam inserts go beyond basic cushioning; they serve as a protective barrier against electrostatic discharge (ESD), a significant concern in the industry. By utilizing specialized materials and precise cutting techniques, manufacturers can create ESD-safe foam inserts that meet the unique requirements of various electronics holland ohio applications.

For instance, anti-static foam for electronics is engineered to minimize the risk of damage caused by static electricity buildup. This is particularly crucial in environments where electronic devices are handled frequently or stored in close proximity. Custom foam inserts allow manufacturers to conform to specific dimensions and specifications, ensuring a perfect fit within enclosures or cases. As a result, these tailored solutions offer enhanced security against physical impacts, vibrations, and—most notably—ESD, contributing to the longevity and reliability of the electronics they protect.

ESD Safety: Why It Matters and How Foam Inserts Ensure Protection

ESD Safety is an essential consideration when handling and packaging sensitive electronic components. ESD stands for Electrostatic Discharge, a sudden flow of electricity between two objects that are at different electrical potentials, which can cause significant damage to delicate equipment. In the context of electronics storage and transportation, protective foam inserts play a crucial role in mitigating these risks.

Custom foam inserts, especially those designed with ESD-safe properties, offer an effective barrier against static discharge. These foam materials are typically treated or constructed with anti-static additives that dissipate electrical charge safely. By placing such inserts within packaging for electronics, the risk of damage from electrostatic buildup is significantly reduced. This is particularly important for industries in Holland, Ohio, where advanced electronic manufacturing and distribution centers rely on precise protection to maintain product integrity.

Applications and Benefits: From Holland, Ohio, to Global Markets

CNC-cut foam inserts have found their way from local workshops in Holland, Ohio to global markets, showcasing their versatility and essential role across various industries. These precise, custom foam solutions are not just a local phenomenon; they are revolutionizing product protection for electronics worldwide. From delicate components needing esd-safe (electrostatic discharge) packaging to intricate gadgets demanding specialized anti-static foam, the applications are vast.

The benefits of CNC-cut foam inserts extend beyond simple protection. They offer lightweight yet robust solutions that can enhance product transport and storage efficiency. With customizable sizes and materials, these foam inserts cater to specific needs—be it for preventing damage during shipping or ensuring sensitive electronics stay in place within a device’s casing. This level of customization has propelled the global markets’ demand for protective foam inserts for electronics, making them indispensable in today’s tech-driven world.