CNC machining is transforming high-volume packaging production, particularly in electronics manufacturing. Custom foam inserts, created with precision CNC technology, offer ESD (Electrostatic Discharge) protection for sensitive components during transit. Holland, Ohio's thriving tech industry has led to specialized protective foam solutions, reducing damage and enhancing product integrity. Integrating CNC technology, custom design, and ESD-safe materials, these foam inserts cater to high-volume production while safeguarding electronics. A leading example in Holland demonstrates the effectiveness of this approach in increasing customer satisfaction and streamlining workflows.

“In today’s fast-paced market, efficient high-volume packaging production is paramount, especially for industries reliant on sophisticated electronics. Computer Numerical Control (CNC) machining emerges as a game-changer, offering precise and customizable solutions. This article explores CNC’s role in packaging, focusing on protective foam inserts tailored to electronic components. From understanding the fundamentals of CNC machining for high-volume needs to delving into ESD-safe and anti-static foam inserts, we provide a comprehensive guide. Discover how a Holland, Ohio, perspective on custom foam inserts enhances shipping security.”

- Understanding CNC Machining for High-Volume Packaging

- Protective Foam Inserts for Electronics: A Holland, Ohio, Perspective

- Custom Foam Inserts: Tailoring Protection to Your Needs

- ESD-Safe Foam Inserts: Preventing Static Damage in Electronics

- Anti-Static Foam for Electronics: A Comprehensive Guide

- Integrating CNC into Packaging Production: Benefits and Best Practices

- Case Study: Enhancing Electronic Shipping with Custom Foam Inserts

Understanding CNC Machining for High-Volume Packaging

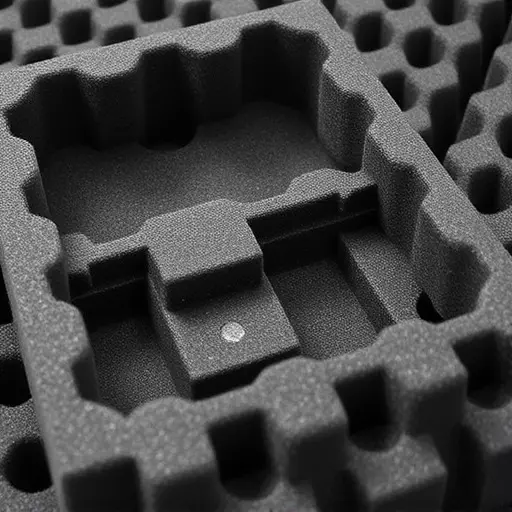

CNC (Computer Numerical Control) Machining is a revolutionary process transforming high-volume packaging production, especially in industries like electronics manufacturing. This advanced technology allows for the creation of precise and customized protective foam inserts tailored to specific product requirements. By programming CNC machines with detailed designs, manufacturers can produce complex foam structures with unmatched accuracy, ensuring electronic components are securely nestled during transportation.

In the case of Holland, Ohio-based companies specializing in electronics, custom foam inserts play a vital role in product protection. ESD (Electrostatic Discharge) safe foam inserts, for instance, are crucial to prevent damage to sensitive electrical components. These inserts are meticulously designed and cut using CNC machinery, offering a cost-effective solution for creating anti-static barriers that safeguard electronics during packaging and shipping.

Protective Foam Inserts for Electronics: A Holland, Ohio, Perspective

In the dynamic landscape of high-volume packaging production, especially for sensitive electronic components, protective foam inserts have emerged as indispensable tools. Holland, Ohio, is a hub where cutting-edge CNC technology meets specialized packaging needs. Custom foam inserts, meticulously designed using advanced CNC machinery, offer unparalleled protection for electronics during transit and storage. These inserts are not just about cushioning; they incorporate ESD-safe (Electrostatic Discharge) materials, ensuring that delicate electronic parts remain untouched by harmful static charges.

The demand for anti-static foam for electronics in Holland and beyond has grown significantly due to the region’s strong presence in the tech industry. Local manufacturers recognize the value of custom-fit, ESD-safe packaging solutions in maintaining product integrity. CNC-cut foam inserts provide a precise, efficient, and cost-effective method to achieve this, ensuring that electronic devices arrive at their destinations in pristine condition, ready for use or further assembly.

Custom Foam Inserts: Tailoring Protection to Your Needs

Custom Foam Inserts play a critical role in high-volume packaging production, particularly for sensitive items like electronics. These precise, tailored solutions ensure that products reach customers in perfect condition, minimizing damage during transit. In Holland, Ohio, companies specializing in protective foam inserts offer advanced ESD-safe (Electrostatic Discharge) options, crucial for safeguarding delicate electronic components from damaging static charges.

By understanding the specific requirements of each product, manufacturers can create custom foam inserts that provide optimal protection. Anti-static foam, for example, is designed to dissipate static electricity, preventing it from reaching sensitive parts. This meticulous attention to detail ensures that electronics are handled with the utmost care, reflecting in the quality and integrity of the products that reach consumers.

ESD-Safe Foam Inserts: Preventing Static Damage in Electronics

ESD-Safe Foam Inserts play a pivotal role in safeguarding electronic components during high-volume packaging production. These specialized protective foam inserts, custom-designed for various product dimensions and shapes, offer an effective solution to prevent static damage. Static electricity, often overlooked, can lead to severe consequences in the electronics industry, causing costly failures and repairs. By incorporating ESD-Safe Foam Inserts into packaging materials, manufacturers ensure that delicate electronic parts are shielded from static build-up during transport and handling.

The foam inserts act as a barrier, absorbing and dissipating any electrostatic charges that may accumulate. This anti-static property is achieved through meticulous material selection and innovative manufacturing processes. With their flexibility and conformability, these custom foam solutions can fit seamlessly into packaging configurations, providing comprehensive protection for sensitive electronics. By adopting ESD-Safe Foam Inserts, manufacturers in Holland, Ohio, and beyond can maintain product integrity, reduce warranty claims, and uphold the reputation of delivering high-quality electronic devices.

Anti-Static Foam for Electronics: A Comprehensive Guide

Anti-Static Foam for Electronics plays a critical role in safeguarding delicate components during high-volume packaging production. Often referred to as ESD (Electrostatic Discharge) safe foam inserts, these specialized materials are designed to mitigate the risk of damage caused by sudden electrical surges. In environments where electronic devices are handled and transported en masse, like manufacturing facilities in Holland, Ohio, the importance of such protective measures cannot be overstated. Custom foam inserts offer a tailored solution, ensuring that every gadget is securely padded against unexpected shocks.

When selecting anti-static foam for electronics, it’s crucial to consider factors like material composition, density, and size compatibility. High-quality ESD-safe foam inserts are crafted from materials that do not generate static electricity, providing a safe haven for sensitive parts. These custom foam solutions can be molded into intricate shapes, fitting snugly within packaging structures while protecting against mechanical impacts and vibrations during transit. By integrating anti-static foam into their packaging strategies, manufacturers in Holland, Ohio, can significantly reduce product defects, maintain quality standards, and ensure customer satisfaction in the competitive electronics market.

Integrating CNC into Packaging Production: Benefits and Best Practices

Integrating Computer Numerical Control (CNC) technology into high-volume packaging production offers numerous advantages for manufacturers, especially in specialized sectors like electronics assembly. One such benefit is the precision and consistency it brings to creating protective foam inserts for sensitive components. CNC machines can cut custom foam inserts with exacting dimensions, ensuring each electronic device is snugly secured during transportation. This level of customization is vital for industries that require ESD-safe (Electrostatic Discharge) packaging, like in Holland, Ohio, where anti-static foam for electronics plays a critical role in maintaining product integrity.

Best practices involve optimizing the design process with CAD software to create efficient toolpaths and material usage. Ensuring the CNC machine is maintained regularly and utilizing high-quality materials, such as ESD-rated foams, can lead to superior packaging solutions. Additionally, implementing automated systems for foam cutting and assembly reduces human error and increases productivity, making it ideal for meeting the demands of high-volume production while maintaining product safety.

Case Study: Enhancing Electronic Shipping with Custom Foam Inserts

In a recent case study, a leading electronic shipping company in Holland, Ohio, sought to optimize their high-volume packaging production for enhanced product protection and improved efficiency. They turned to Computer Numerical Control (CNC) technology and specifically custom foam inserts to revolutionize their packing process. By implementing ESD-safe (Electrostatic Discharge) foam inserts, the company could ensure the safety of delicate electronic components during transit.

The use of custom foam inserts allowed for precise packaging solutions tailored to various electronic devices. These anti-static foam inserts, meticulously designed and cut using CNC machinery, provided superior shock absorption and protection against physical damage. The result was a significant reduction in product returns due to shipping-related issues, thereby increasing customer satisfaction and streamlining the overall production workflow.